Bed Positioning

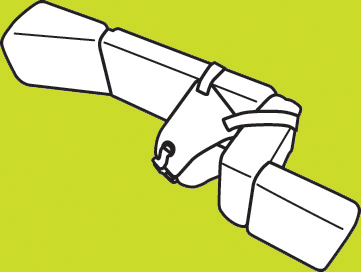

We manufacture three main types of equipment that can assist with a person's bed positioning needs. Sidelyers provide a rigid support and are custom made to fit. Wedges & Bolsters are also available and are manufactured to suit the specific needs of the individual.

Custom Commode Seating

Custom commode seating has traditionally been a challenge due to necessary hygienic requirements. To overcome this obstacle, we waterproof our systems with silicone, use non-porous foams for padding and integrate plastics that do not absorb moisture. Custom commode wheelchair seating can be custom contoured or planar in shape.

Computer

success.

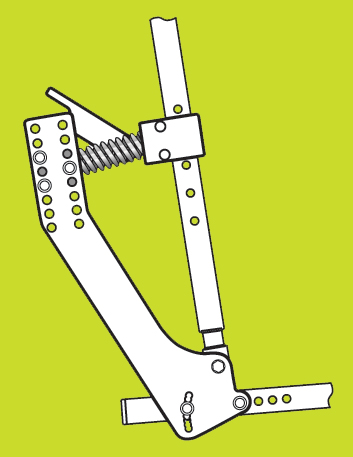

Dynamic Systems

PPS builds three types of dynamic components that can be added to the backrest, head support and/or footrests of wheelchairs. Dynamic systems can provide relief from body movements and prevent excessive wheelchair frame damage. The most common type we provide is the dynamic backrest.

Trays

Commercial trays can be modified to suit the individual or Priority Posture Systems can custom build one to suit a variety of needs. Custom options include material choice (black ABS plastic or clear Lexan plastic), size, custom shape & cut-outs, padding, mounting hardware, etc.

And More...

We are always looking for new and exciting projects that require innovation and the opportunity to design something new.

At PPS our primary focus is building custom contoured seating systems for wheelchairs. However, we are not limited to seating systems. We also fabricate many other alternative positioning devices and adapt mobility devices. We pride ourselves in always looking for new and unique challenges in the rehab world. Below are descriptions of some of the products we build.

We provide state of the art custom molded and custom carved wheelchair seating systems. Sometimes the ideal product for a client is a combination of both types of seating, usually a carved foam seat cushion with a custom molded backrest shape.

Custom molded seating systems can either be constructed using poured foam techniques or by molding ABS plastic. The type of system best suited for a client depends on their specific needs. Poured foam systems are softer but heavier while molded ABS is lighter but more firm. There are many other considerations that can be discussed during the Specifications Appointment.

Custom Seating . Our Primary Focus

Custom Commode Seating

Dynamic Back Hardware

Sidelyer Bed Positioner

Wedge Positioner

Products

Hybrid system with custom contoured

foam backrest and planar foam seat

Custom contoured ABS shell back

Products